Categoria

- moldes de produção automotiva

- moldes de prototipagem rápida

- moldes de peças de precisão

- moldes de peças transparentes

- moldes de peças de parede fina

- Desparafusar moldes de peças

- Moldes de peças sobremoldadas

- Moldes de peças de dois tiros

- Moldes de peças assistidas a gás

- Molde de peça de espuma PU

- Molde de múltiplas cavidades

Molde de copo de plástico de parede fina de alta qualidade com 8 cavidades

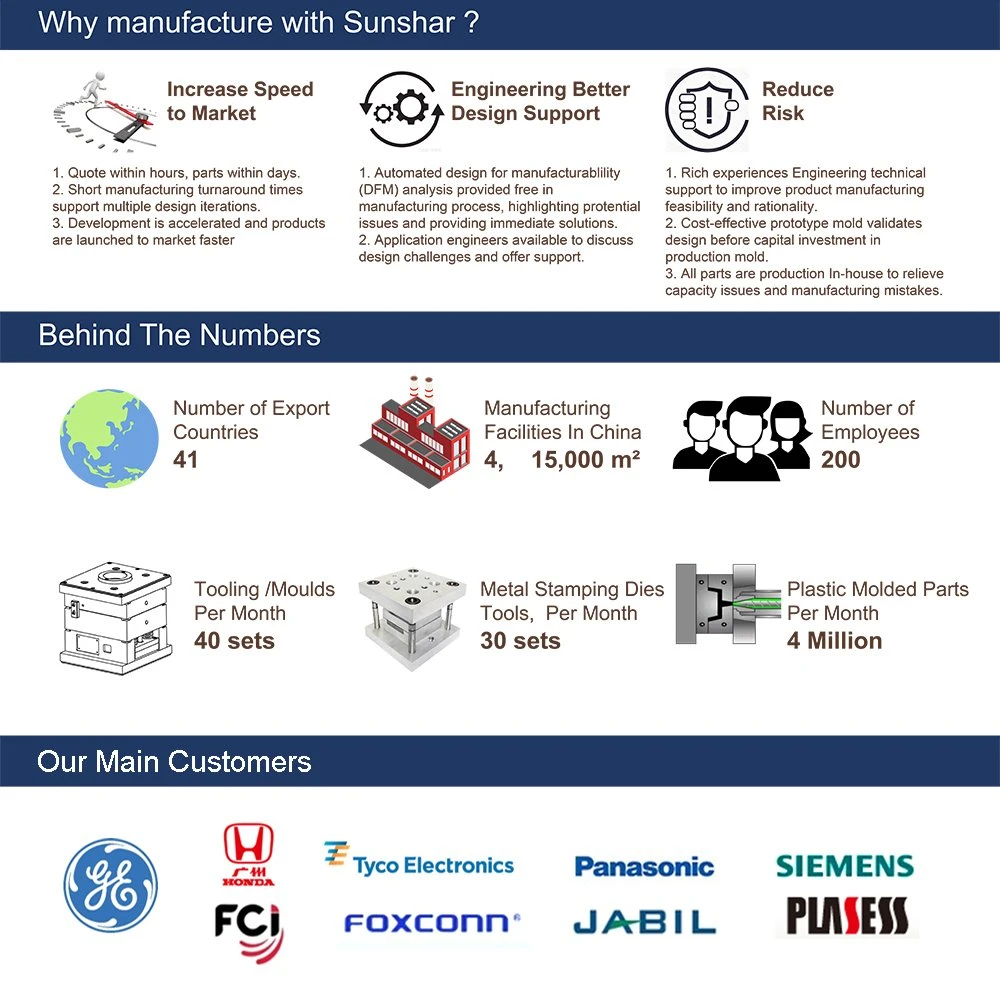

Por que escolher a Sunshar? A Sunshar fornece serviço completo para moldagem por injeção de plástico de alto volume e té

Informação básica

| Modelo Nº. | molde de plástico |

| Material plástico | PP |

| Corredor | Corredor quente |

| Portão | Bico da Válvula |

| Cavidade do Molde | 8 |

| Tipo de combinação de processos | Modo de processo progressivo |

| Tempo de Ciclo | 7s |

| software de design | e |

| Padrão | Dme |

| Personalizado | Personalizado |

| Pacote de transporte | Embalagem de madeira |

| Especificação | 123*123 |

| Marca comercial | Sunshar |

| Origem | China |

| Capacidade de produção | 100 |

Descrição do produto

| SUNSHAR PRECISION TECHNOLOGY CO., LTD | |

| ADICIONAR: Distrito de Shangjiao, cidade de Chan'an, cidade de Dongguan, província de Guangdong, China. 523878, | |

| Especificações do molde/ferramenta Sunshar: | |

| Padrões de molde: | AISI, DIN, JIS |

| Padrão de Base de Molde: | HASCO, DME, LKM, FUTABA |

| Molde de Aço: | H13, 1040, 420, P20, 0-1, S-7, D2, A2, 1,2343, 1,2344, 1,2083, 1,2311, 1,2379, 1,2510, 1,2767, 1,1730, P5, NAK55, NAK80, SKD61, SKD 5 1, S136, S136H , 8407, M333, 718H |

| PC, PC+ABS, ABS, PBT, LCP, PBT+GF, POM, Nylon, PEEK, PE, HDPE, PP, AS, PS, PP+PULVISTALCI, PET, TPU, PPS, PSU, PPO | |

Anterior: Venda imperdível Moldes de caixa de recipiente de comida de parede fina Moldes de caixa de recipiente de comida

Próximo: Injeção de plástico Talheres Descartáveis Louça Parede Fina Microondas Tigela Almoço Ketchup Recipiente Fast Food Caixa Prato Copo Braçadeira Colher Garfo Faca Molde

Enviar consulta

Enviar